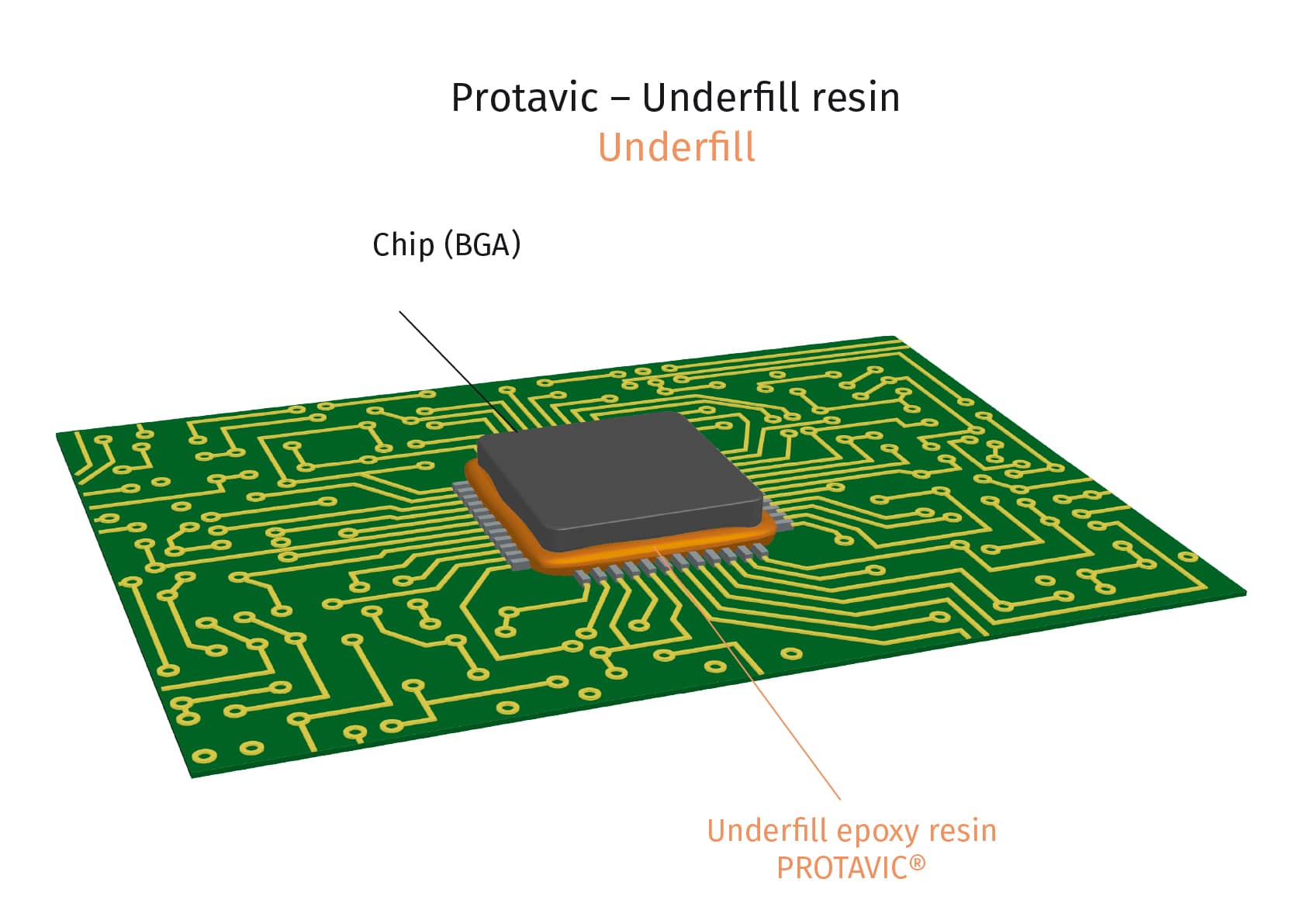

Underfill

Underfill is a liquid resin that works by capillarity to protect components from shocks, drops and vibrations.

The insulating filling improves the reliability of the weld points, particularly during thermal stress and drop tests.

The low thermal expansion of PROTAVIC Underfill makes it effective in a variety of uses.

Some examples are listed in the table below.

Technical description

Name

Color

Chemistry

Density

Viscosity at 25°C (mPa.s)

Glass transition temperature (TG)

CTE (ppm/°C)

Shore hardness

Thermal conductivity (W/(m.K))

Open time

Polymerization / Crosslinking

Storage

PROTAVIC® ANE 10932

White

Epoxy

1,65

25000

150°C

25

D90

-

>3 days

3 min at 150°C

6 months at -40°C

PROTAVIC® ANE 10956-R

Cream

Epoxy

1.6

10000

125°C

25

D94

-

2 days

10 min at 150°C

6 months at -20°C

PROTAVIC® ANE 20960

Black

Epoxy

1.6

6000

165°C

17

D90

1

5 days

20 sec at 150°C

3 months at -20°C

PROTAVIC® ANE 10932

White

Epoxy

Chemistry1,65

Density25000

Viscosity at 25°C (mPa.s)150°C

Glass transition temperature (TG)25

CTE (ppm/°C)D90

Shore hardness-

Thermal conductivity (W/(m.K))>3 days

Open time3 min at 150°C

Polymerization / Crosslinking6 months at -40°C

StoragePROTAVIC® ANE 10956-R

Cream

Epoxy

Chemistry1.6

Density10000

Viscosity at 25°C (mPa.s)125°C

Glass transition temperature (TG)25

CTE (ppm/°C)D94

Shore hardness-

Thermal conductivity (W/(m.K))2 days

Open time10 min at 150°C

Polymerization / Crosslinking6 months at -20°C

StoragePROTAVIC® ANE 20960

Black

Epoxy

Chemistry1.6

Density6000

Viscosity at 25°C (mPa.s)165°C

Glass transition temperature (TG)17

CTE (ppm/°C)D90

Shore hardness1

Thermal conductivity (W/(m.K))5 days

Open time20 sec at 150°C

Polymerization / Crosslinking3 months at -20°C

Storage