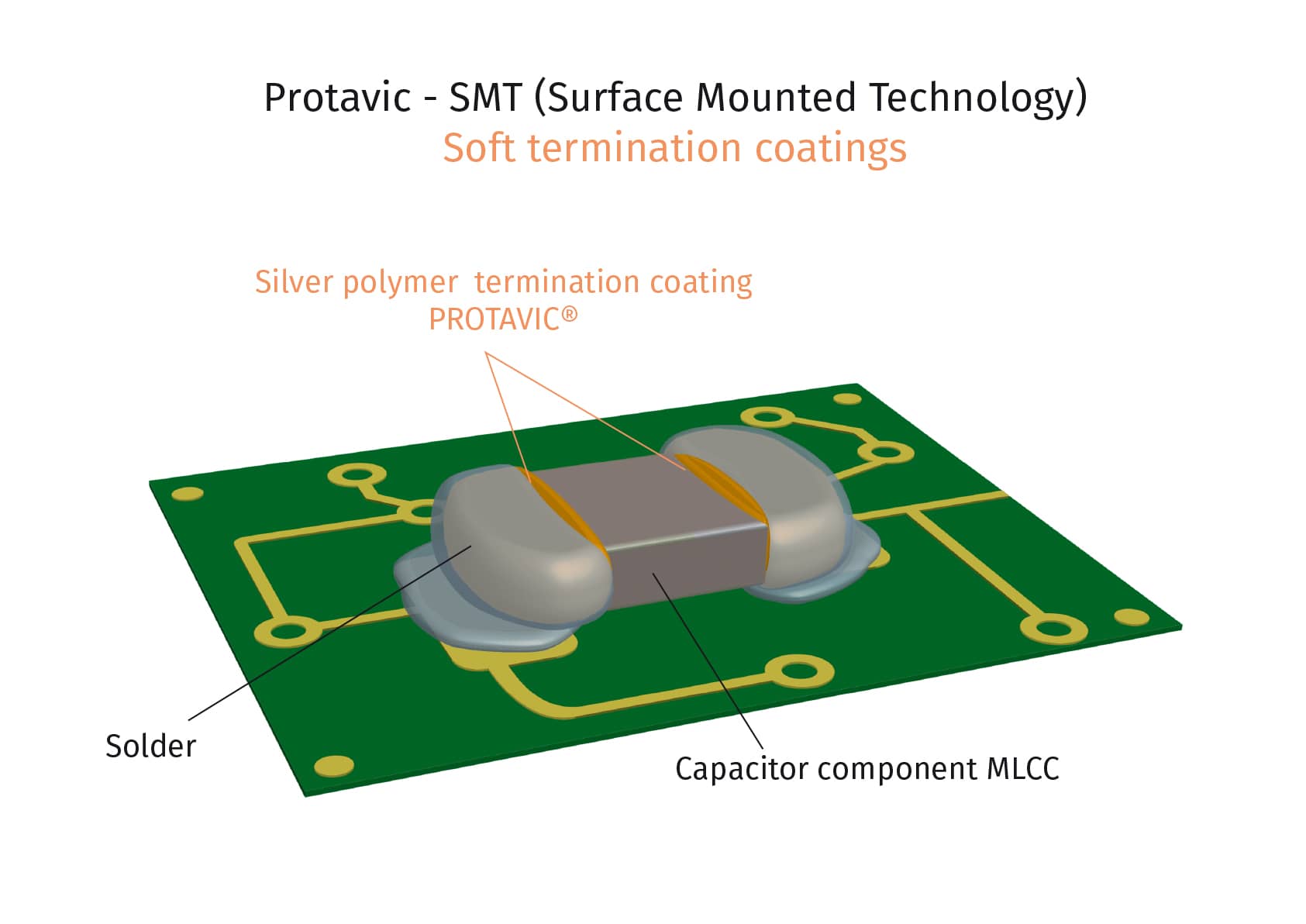

Terminations

PROTAVIC termination products protect against cracks that can arise during surface mounted device (SMD) assembly from picking and placing, soldering and handling all the way through to the final tests of the circuit board (PCBA).

By providing flexibility that dramatically reduces stress cracking, the terminations developed by PROTAVIC greatly reduce the possibility of capacitor failure.

Some examples are listed in the table below.

Technical description

Name

Color

Chemistry

Density

Viscosity at 25°C (mPa.s)

Glass transition temperature (TG)

CTE (ppm/°C)

Electrical resistance (mΩ.cm)

Percent load

Open time

Polymerization / Crosslinking

Storage

PROTAVIC® BCE 30370

Silver

Epoxy

2.9

10000

90°C

-

0.2

69

16 hours

Drying + 1h at 150°C

6 months at -20°C

PROTAVIC® BCE 30371

Silver

Epoxy

2.9

6000

90°C

-

0.2

65

16 hours

Drying + 1h at 150°C

6 months at -20°C

PROTAVIC® BCE 30374M

Silver

Epoxy

3.1

4500

90°C

65

0.05

-

16 hours

Drying + 30 min at 180°C

6 months at 10°C

PROTAVIC® BCE 30375M

Silver

Epoxy

2.7

2600

90°C

65

0.2

65

-

Drying + 1h at 150°C

6 months at -20°C

PROTAVIC® BCE 30375M HV

Silver

Epoxy

2.7

5,000

90°C

65

0.2

65

-

Drying + 1h at 150°C

6 months at -20°C

PROTAVIC® BCE 60462

Silver

Epoxy

1.6

1000

80°C

-

0.2

63

-

30 min at 20°C + 1h at 125°C

1 year at -20°C

PROTAVIC® BCE 30370

Silver

Epoxy

Chemistry2.9

Density10000

Viscosity at 25°C (mPa.s)90°C

Glass transition temperature (TG)-

CTE (ppm/°C)0.2

Electrical resistance (mΩ.cm)69

Percent load16 hours

Open timeDrying + 1h at 150°C

Polymerization / Crosslinking6 months at -20°C

StoragePROTAVIC® BCE 30371

Silver

Epoxy

Chemistry2.9

Density6000

Viscosity at 25°C (mPa.s)90°C

Glass transition temperature (TG)-

CTE (ppm/°C)0.2

Electrical resistance (mΩ.cm)65

Percent load16 hours

Open timeDrying + 1h at 150°C

Polymerization / Crosslinking6 months at -20°C

StoragePROTAVIC® BCE 30374M

Silver

Epoxy

Chemistry3.1

Density4500

Viscosity at 25°C (mPa.s)90°C

Glass transition temperature (TG)65

CTE (ppm/°C)0.05

Electrical resistance (mΩ.cm)-

Percent load16 hours

Open timeDrying + 30 min at 180°C

Polymerization / Crosslinking6 months at 10°C

StoragePROTAVIC® BCE 30375M

Silver

Epoxy

Chemistry2.7

Density2600

Viscosity at 25°C (mPa.s)90°C

Glass transition temperature (TG)65

CTE (ppm/°C)0.2

Electrical resistance (mΩ.cm)65

Percent load-

Open timeDrying + 1h at 150°C

Polymerization / Crosslinking6 months at -20°C

StoragePROTAVIC® BCE 30375M HV

Silver

Epoxy

Chemistry2.7

Density5,000

Viscosity at 25°C (mPa.s)90°C

Glass transition temperature (TG)65

CTE (ppm/°C)0.2

Electrical resistance (mΩ.cm)65

Percent load-

Open timeDrying + 1h at 150°C

Polymerization / Crosslinking6 months at -20°C

StoragePROTAVIC® BCE 60462

Silver

Epoxy

Chemistry1.6

Density1000

Viscosity at 25°C (mPa.s)80°C

Glass transition temperature (TG)-

CTE (ppm/°C)0.2

Electrical resistance (mΩ.cm)63

Percent load-

Open time30 min at 20°C + 1h at 125°C

Polymerization / Crosslinking1 year at -20°C

Storage