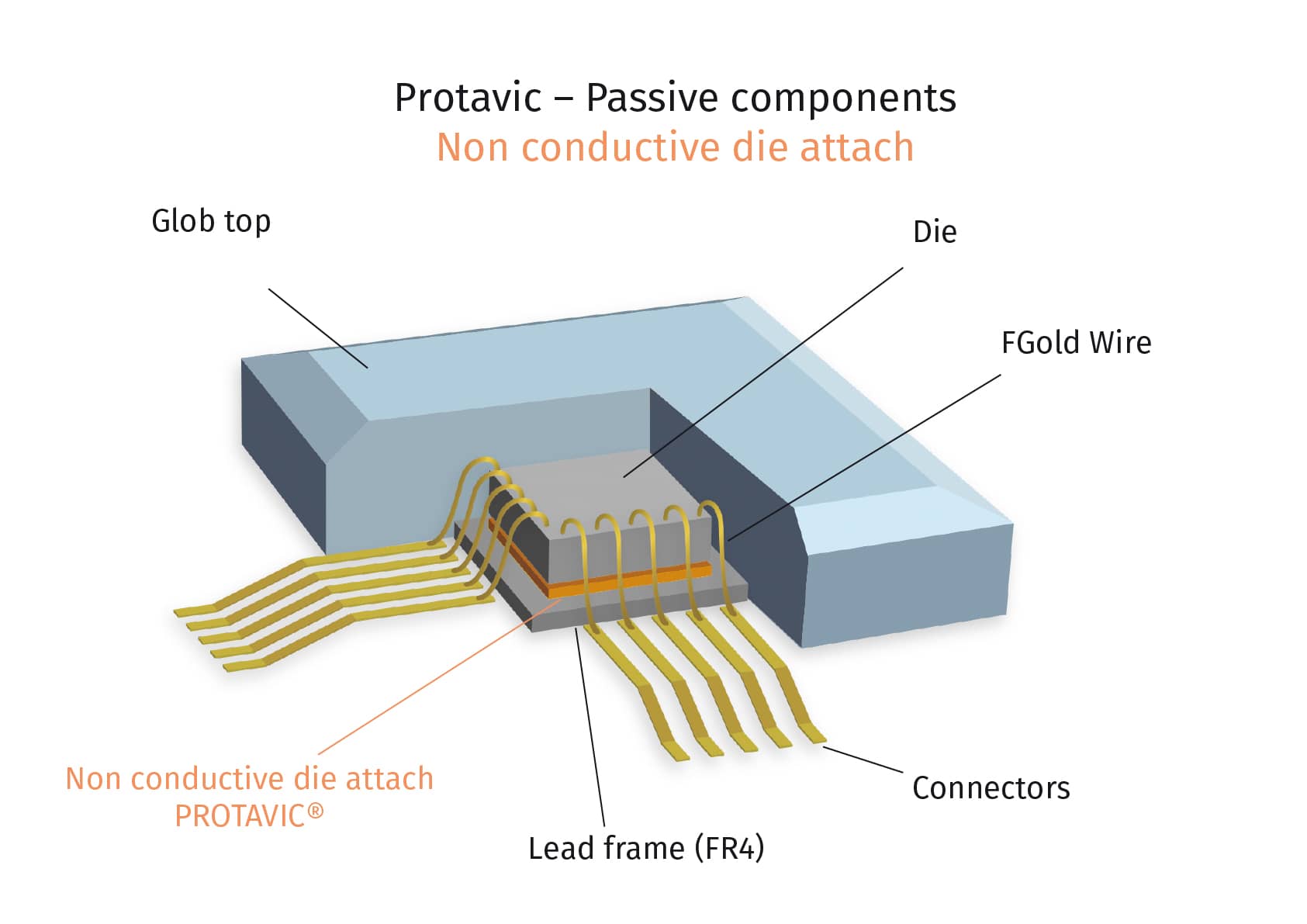

Die-Attach

PROTAVIC offers a range of adhesive products designed for Die-Attach.

The choice of the chemistry depends on the final application and requirements:

- epoxies,

- acrylics,

- polyimides

- or hybrids

The adhesives can be insulating or conductive with thermal conductivity up to 28W/mK.

PROTAVIC products have high ionic purity and low degassing, so they are appropriate for use in the defense and aerospace industries.

Some examples are listed in the table below.

Technical description

Name

Color

Chemistry

Density

Viscosity at 25°C (mPa.s)

Glass transition temperature (TG)

CTE (ppm/°C)

Thermal conductivity (W/(m.K))

Electrical resistance (mΩ.cm)

Open time

Polymerization / Crosslinking

Storage

PROTAVIC® ACE 10100

Sliver

Epoxy

2,9

2500

75°C

45

2,5

<0,3

<1 day

2 min at 175°C

3 months at -20°C

PROTAVIC® ACE 10131

Silver

Epoxy

2.9

2000

75°C

45

2.5

<0.3

48 hours

90 min at 75°C

6 months at -20°C

PROTAVIC® ACE 10100

Sliver

Epoxy

Chemistry2,9

Density2500

Viscosity at 25°C (mPa.s)75°C

Glass transition temperature (TG)45

CTE (ppm/°C)2,5

Thermal conductivity (W/(m.K))<0,3

Electrical resistance (mΩ.cm)<1 day

Open time2 min at 175°C

Polymerization / Crosslinking3 months at -20°C

StoragePROTAVIC® ACE 10131

Silver

Epoxy

Chemistry2.9

Density2000

Viscosity at 25°C (mPa.s)75°C

Glass transition temperature (TG)45

CTE (ppm/°C)2.5

Thermal conductivity (W/(m.K))<0.3

Electrical resistance (mΩ.cm)48 hours

Open time90 min at 75°C

Polymerization / Crosslinking6 months at -20°C

Storage