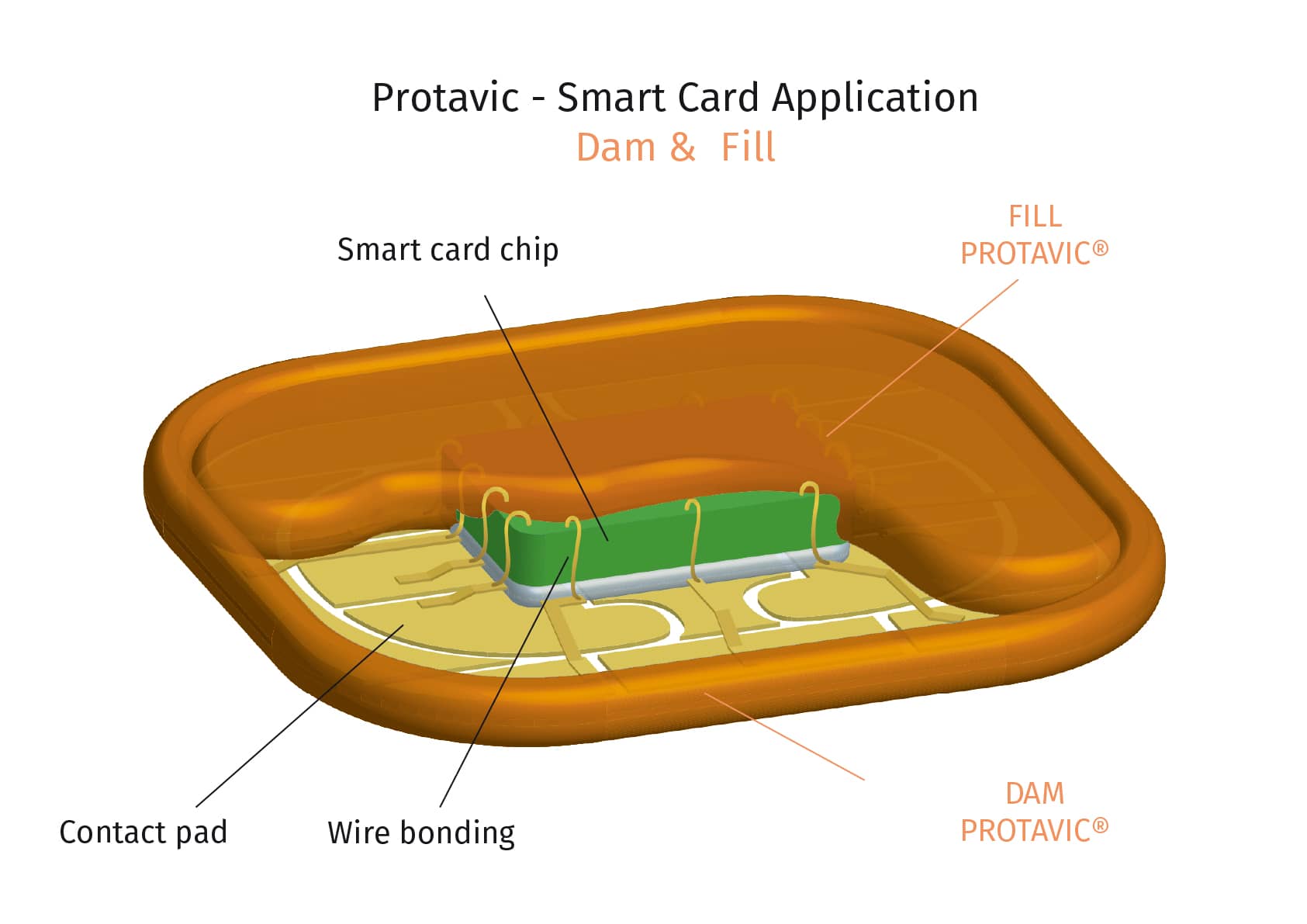

Dam & Fill and Glob-Top

PROTAVIC’s Dam & Fill reduces warping and provides superior protection during torsion and bending tests undergone by micro-connectors during validation.

PROTAVIC’s Glob-Top is intended for smaller chips.

PROTAVIC’s Dam & Fill and Glob-Top ranges offer different curing options for protecting smart card micromodules:

- UV curing allows for quicker processing in mass production

- Thermal curing allows for low coefficients of thermal expansion (CTE) and high glass transition temperatures (Tg).

Some examples are listed in the table below.

Technical description

Name

Color

Chemistry

Density

Viscosity at 25°C (mPa.s)

Glass transition temperature (TG)

CTE (ppm/°C)

Shore hardness

Thermal conductivity (W/(m.K))

Use

Dielectric strength (kV/mm)

Open time

Polymerization / Crosslinking

Storage

PROTAVIC® PNE 30270

Black

Epoxy

1,7

70000

150°C

20

D85

0,7

Glob top

>15

5 days

35 min at 120°C + 1h at 150°C

3 months at -20°C

PROTAVIC® PNE 90300

White

Epoxy

1.4

16000

24

140

D55

-

Dam

-

-

30 sec at 120 mW/cm² UV A

6 months at 5°C

PROTAVIC® PNE 90301

White

Epoxy

1.47

2600

50°C

100

D80

-

Fill

-

-

30 sec at 120mW/cm² UV A

6 months at 5°C

PROTAVIC® PNE 30270

Black

Epoxy

Chemistry1,7

Density70000

Viscosity at 25°C (mPa.s)150°C

Glass transition temperature (TG)20

CTE (ppm/°C)D85

Shore hardness0,7

Thermal conductivity (W/(m.K))Glob top

Use>15

Dielectric strength (kV/mm)5 days

Open time35 min at 120°C + 1h at 150°C

Polymerization / Crosslinking3 months at -20°C

StoragePROTAVIC® PNE 90300

White

Epoxy

Chemistry1.4

Density16000

Viscosity at 25°C (mPa.s)24

Glass transition temperature (TG)140

CTE (ppm/°C)D55

Shore hardness-

Thermal conductivity (W/(m.K))Dam

Use-

Dielectric strength (kV/mm)-

Open time30 sec at 120 mW/cm² UV A

Polymerization / Crosslinking6 months at 5°C

StoragePROTAVIC® PNE 90301

White

Epoxy

Chemistry1.47

Density2600

Viscosity at 25°C (mPa.s)50°C

Glass transition temperature (TG)100

CTE (ppm/°C)D80

Shore hardness-

Thermal conductivity (W/(m.K))Fill

Use-

Dielectric strength (kV/mm)-

Open time30 sec at 120mW/cm² UV A

Polymerization / Crosslinking6 months at 5°C

Storage